——Intelligent equipment promotes wood processing towards green manufacturing

With the increasing demand for efficiency and environmental protection in the global wood processing industry, square wood multi-blade saw is becoming the core equipment for industry upgrading with its revolutionary design. This equipment not only significantly improves the utilization rate of wood, but also injects new vitality of efficiency and safety into the traditional woodworking industry through a fully enclosed structure, automation technology and intelligent dust removal system.

1. Core advantages: efficiency, safety and environmental protection

(1). Efficient production and cost saving

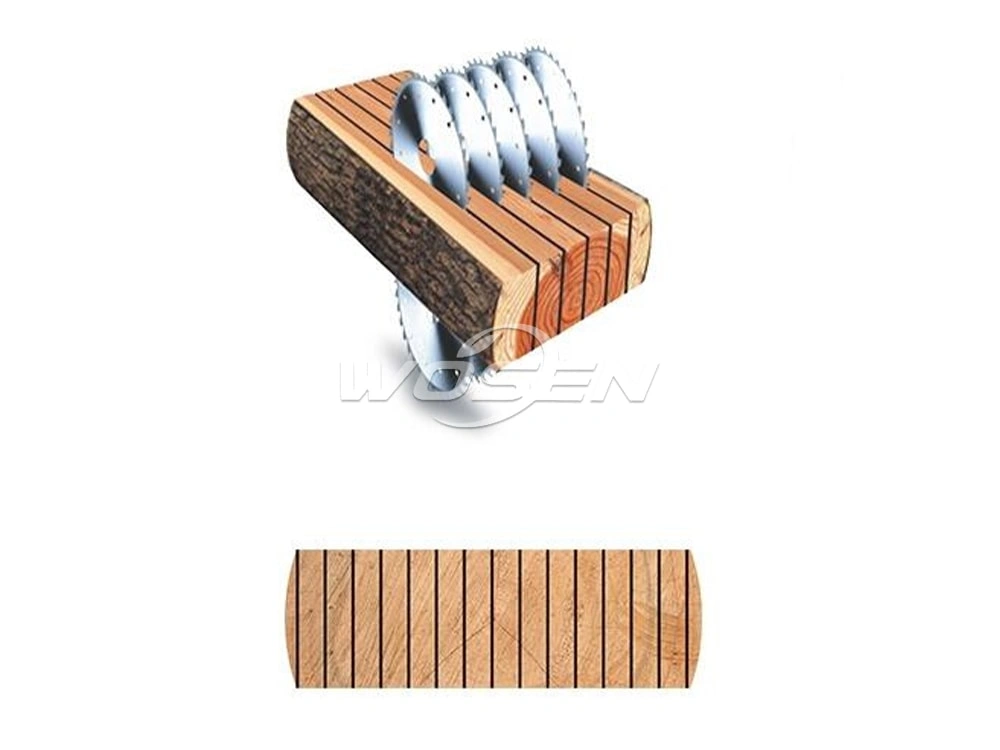

The square wood multi-blade saw adopts a multi-saw blade combination design, which can cut logs into multiple equal-width strips at one time, with a processing speed of up to 8 meters/minute. The daily output of a single device can reach 10-50 cubic meters, which is 4-10 times that of a traditional band saw. For example, a device can process a 2-meter-long log into 8-9 pieces of standard boards in just a dozen seconds, greatly reducing time and labor costs.

(2). Fully enclosed design to ensure safe operation

The exposed transmission device and saw blade of traditional band saws are prone to cause work-related injuries, while the square wood multi-blade saw minimizes safety hazards through a fully enclosed structure, double bulletproof devices and a power feeding system. Its infrared alignment and pressure wheel device further ensure smooth feeding and reduce the risk of material jamming.

(3). Environmental protection and consumption reduction to achieve green production

The equipment is equipped with an efficient dust removal system, and the sawdust is centrally processed through a closed chip removal channel, reducing dust pollution by more than 80%. The cooling water recycling technology avoids wastewater discharge, and the low noise design (the decibel value is significantly lower than that of traditional equipment) meets the environmental protection standards of modern factories.

2. Technological innovation: fusion of intelligence and high precision

Ultra-thin alloy saw blades: using high-quality alloy saw blades with a thickness of only 1-2 mm, the saw path loss is reduced by 15%, and the wood utilization rate is increased to 80-88%, which is especially suitable for processing short logs with a diameter as small as 4 cm.

Automation upgrade: The new equipment supports multi-power feeding throughout the process and integrates patented axial water spray technology to extend the life of the saw blade by more than 30%. Some high-end models also introduce intelligent temperature control systems to prevent saw blade deformation caused by high temperature.

Flexible customization: The mainstream models in the market cover processing thicknesses from 1cm to 30cm, support personalized customization, and meet the needs of multiple scenarios such as furniture manufacturing and building templates.

3. Market prospects: Global demand surges, and automation becomes the mainstream

According to industry analysis, the square wood multi-blade saw is known as the "slot machine in the field of wood processing", and its high-efficiency characteristics make it continue to sell well in domestic and foreign markets. With the growing demand for mass production in the furniture industry, automated multi-blade saw equipment has occupied more than 60% of the market share. By absorbing international technology and innovating independently, Chinese manufacturers have launched equipment that combines price advantages and high performance, and are exported to Southeast Asia, Europe and other places.

Square wood multi-blade saw-the future engine of the woodworking industry

Through technological innovation, the square wood multi-blade saw not only solves the efficiency and safety bottlenecks in traditional processing, but also promotes the sustainable development of the industry with the concept of green manufacturing. With the deep integration of intelligent and automated technologies, this equipment will continue to lead the wave of change in the global wood processing industry.

Name: Ada Wang

Phone:+86183 54378827

Email: [email protected]

Our company wholeheartedly welcomes new and old fiends from a walks of life to visit,communicate and negotiate, and seek common development,cooperaion andwin-win, and work together to create a better tomorrow.